As part of a unit in school learning to make commercial / institutional furniture, I made this jig to help with making a leg assembly for a bench. You can see the completed project's plans here, and the photos here.

The jig is rather simple. There's an MDF panel slightly larger than the perimeter dimensions of the leg assembly, with a curve at the top that will be the reference face for the bearing on the Shaper (to create the top profile on the legs). To keep the assembly in place, the jig has a pocket half the depth of the panel that a raised insert fits into. The middle of the leg assembly then fits around the insert.

Cutting the jig, pocket, and insert on the CNC was super quick, and made it easy to ensure that the assembly is perfectly aligned when cutting the top profile, as well as secure from moving around (later I added some toggle clamps for extra security). The jig is also very useful when making layout lines for dominoes when assembling each of the leg components.

|

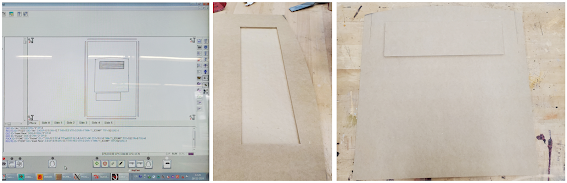

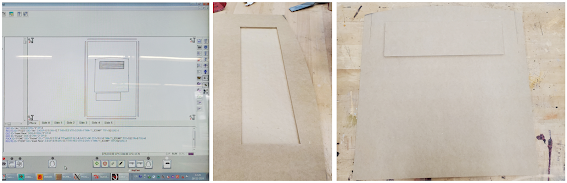

| CNC File (Left), Pocket in Jig (Middle), Jig with Fitted Insert (Right) |

|

Leg Assembly Placed in Jig - Rough Bandsaw of Curve (Left), Cutting the Top Profile on the Shaper (Middle), Finished Leg Assemblies (Right)

|

|

Completed Bench

|

Ah yes, the humble jig—the unsung hero of woodworking. While others brag about their projects, jigs quietly hold things together, align the universe, and whisper, ‘I got you, buddy.’ Yours seems to have reached jig enlightenment. Bravo!

ReplyDeleteIt's true, not enough people are gettin' jiggy with it

Delete